INTMET Clustering Conference

Fostering Innovation in the Iberian Pyrite Belt

Date: January 23rd 2019

Time: 9:00 – 17:30

Venue: Consulado General de Portugal, Avenida El Cid, 1, 41004 Seville, Spain

The aim of the clustering conference is to facilitate the meeting of innovation agents and the Metal Industry in Europe. A special focus will be set on the case of the Iberian Belt, where the new identify techniques can help to unlock the actual barriers to the exploitation of these polymetallic concentrates. Different R&D European projects will present their promising results as a way to unlock the actual technological barriers to the exploitation of European Raw Materials sources.

Representatives from the European Commission, Andalusia (Spain) and Alentejo (Portugal), and the mining industry will contribute to the conference to foster the technological innovation in the region.

In this framework, the INTMET project (Integrated innovative metallurgical system to benefit efficiently polymetallic, complex and low-grade ores and concentrates) will present its three years results for the development of a new and efficient technology to deal with low-grade, complex ores, combining innovative hydrometallurgical processes (atmospheric, pressure and bioleaching) and novel more effective metals extraction techniques. The results are very positive and provide a significant step forward in winning metals from polymetallic, complex and low-grade ores in a sustainable but also economic way by the application of a new mining (mine-to-metal) business model based on the technology breakthroughs.

Daniel Cios, Policy Assistant, Resource Efficiency and Raw Materials Unit, European Commission.

Key notes from EU representative: Raw Materials sector in Horizon-2020 and future Horizon-Europe

Marcin Sadowski, Head of Sector Raw Materials, European Commission.

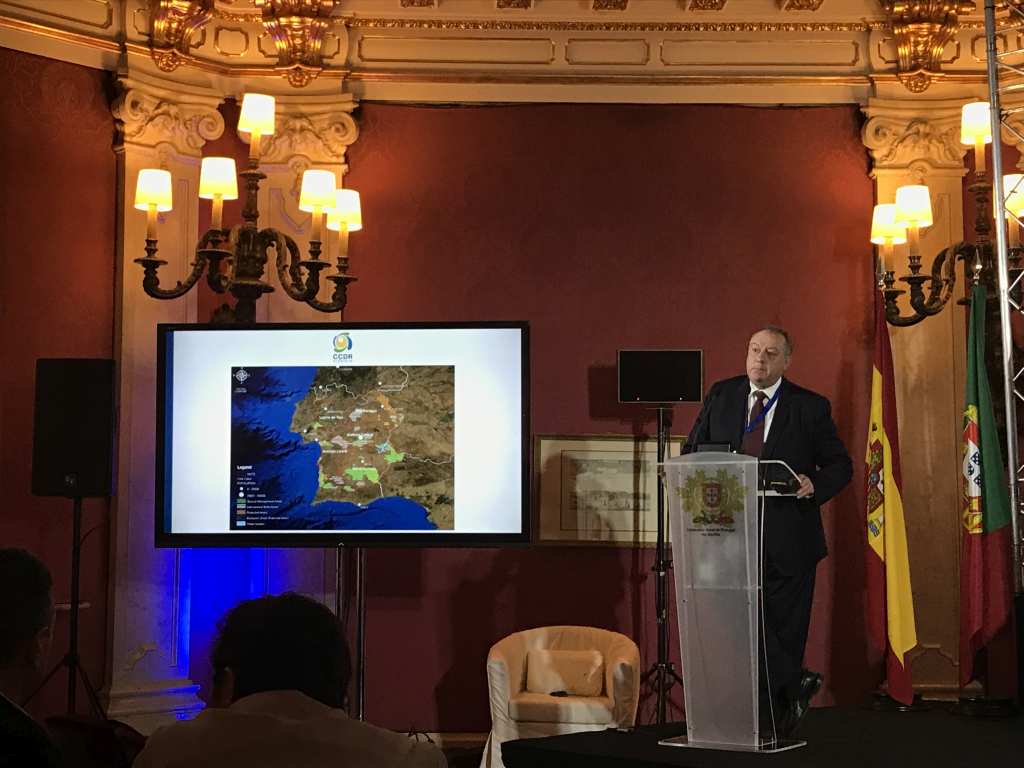

Key notes from Alentejo representative: Importance of mining business for Alentejo, Portugal

Jorge Pulido Valente, Vice-Presidente da CCDR Alentejo.

Key notes from Junta de Andalucia representative: Importance of mining business for Andalucia, Spain

Natalia González Hereza, Directora General de Industria, Energía y Minas, Junta de Andalucía.

Belt, Spanish territory

Manuel José García, Vocal de AMINER.

Key notes from Mineral Resources Cluster representative: Opportunities and risks for mining business in

the Iberian Pyrite Belt, Portuguese territory

Luís Martins, Presidente do Conselho de Administração, Mineral Resources Cluster.

- INTMET (Francisco Sánchez, Cobre Las Cruces)

- FAME (Marco Roscher, Saxore Bergbau GmbH)

- INFACT (Petya Atanasova, HZDR)

- MIREU (Wolfgang Reimer, GKZ Freiberg eV)

- Almina (Portugal)

- Atalaya Mining (Spain)

- Cobre Las Cruces (Spain)

- Mina Aguas Teñidas (Spain)

- Minera Los Frailes (Spain)

- Somincor (Portugal)

Speakers to be defined.

- INTMET (Carlos Frías, Cobre Las Cruces)

- FAME (Marco Roscher, Saxore Bergbau GmbH)

- INFACT (Petya Atanasova, HZDR)

- MIREU (Wolfgang Reimer, GKZ Freiberg eV)

Open questions and recommendations

With the following questionnaire, INTMET would like to invite you to take part in the further course of process development and its commercial application. It is a recommendation of the European Commission that funded research projects should look for commercialisation of their results. Therefore, we are forwarding a couple of questions to obtain an overview of the potential market for our process. The objective of the questionnaire is to collect information as detailed as possible about the processing of low-grade and/or complex ores in order to adapt the parameters of the INTMET process and, subsequently, identify potential application cases for it.

The questions mainly relate to your operational environment and parameters of the input and output of the processes you are using. To identify the individual case in the further assessment process, few questions concerning your organisation are included as well.

We would very much appreciate your contribution to our work. In any case of question, please don’t hesitate to contact us.

We thank you very much in advance for your contribution.

Get an overview of INTMET’s targets and results (6’28, EN)

Without mineral raw materials that are still today produced by mining and subsequent processing, almost nothing can be manufactured. That what comes out of the earth crust, the metal ores, are nowadays getting more and more complex, and the ore grade is becoming lower. “Today’s conventional technologies show some limitations and difficulties to these complex ores. They produce an individual concentrate, separate for each metal of concern. The INTMET proposal is totally different. It has all metals together in one bulk concentrate and then applying hydrometallurgical technologies to produce the high value metals onsite in the mine instead of selling the concentrates. This will lead to a more robust economic and sustainable business”, explains project coordinator Carlos Frías INTMET’s lead of technology.

Statements of INTMET experts about specific project topics

Microorganisms that extract metals, another technology tested in INTMET, Petrus van Staden, MINTEK

Atmospheric leaching developed by INTMET project, Natalia Moreno Bermejo, Cobre las Cruces – EN

Lixiviación atmosférica desarrollada en el proyecto INTMET, Natalia Moreno Bermejo, Cobre las Cruces

The innovation of the hydrometallurgical approach of INTMET, Carlos Frias, Cobre las Cruces

INTMET’s results are applicable in mining regions worldwide, Carlos Frias, Cobre las Cruces

INTMET – an unique opportunity for mines dealing with complex ores, Carlos Frias, Cobre las Cruces

INTMET – How to treat wastes and effluents? Carmen Estepa Molina, AGQ_EN

¿Cómo tratar los materiales de desecho y los efluentes mineros? Carmen Estepa Molina, AGQ

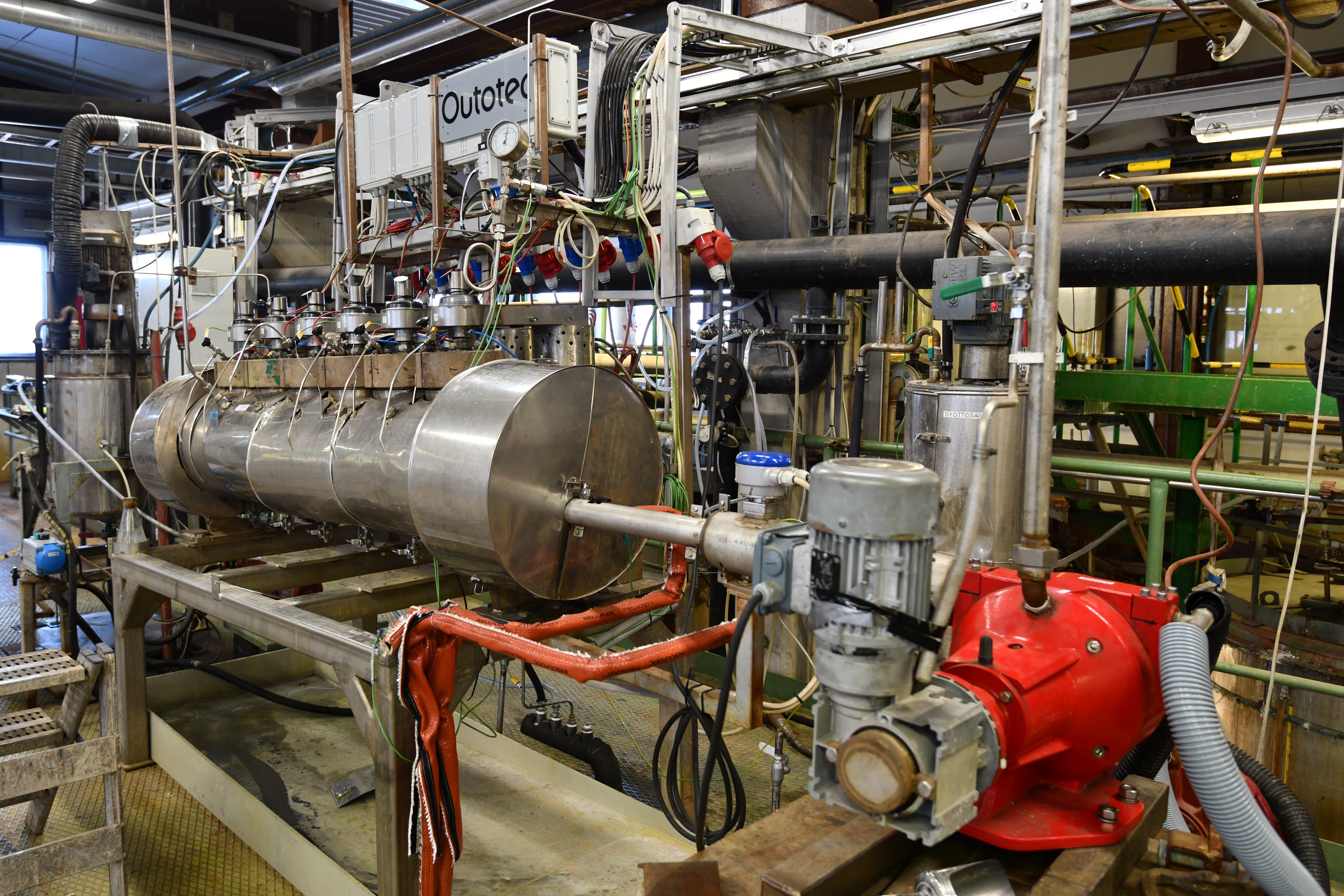

Pressure leaching, one of the technologies tested in INTMET, explained by Mika Haapalainen, Outotec

PMS project opens a new horizon for COBRE LAS CRUCES

TV Bor RTB prijem za clanove konzorcijuma INTMET 21022018

Local TV in Bor, Serbia, reported about INTMET project during the consortium meeting, 20-21 Feb 2018

Welcome to INTMET

“Integrated innovative metallurgical system to benefit efficiently polymetallic, complex and low grade ores and concentrates.”

The project

INTMET’s approach represents a unique technological breakthrough to overcome the limitations related to difficult low grade and complex ores to achieve high efficient recovery of valuable metals (Cu, Zn, Pb, Ag) and CRM (Co, In, Sb). Main objective of INTMET is applying on-site mine-to-metal hydroprocessing of the produced concentrates enhancing substantially raw materials efficiency thanks to increase Cu+Zn+Pb recovery over 60% vs. existing selective flotation. Three innovative hydrometallurgical processes (atmospheric, pressure and bioleaching), and novel more effective metals extraction techniques (e.g. Cu/Zn-SX-EW, chloride media, MSA, etc.) will be developed and tested at relevant environment aiming to maximise metal recovery yield and minimising energy consumption and environmental footprint. Additionally, secondary materials like tailings and metallurgical wastes will be tested as well for metals recovery and sulphur valorisation. The technical, environmental and economic feasibility of the entire approaches will be evaluated to ensure a real business solution of the integrated INTMET process.

INTMET will be economically viable thanks to diversification of products (Cu, Zn, Pb), high-profitable solution (producing commodities not concentrates), with lower operation and environmental costs (on-site hydroprocessing will avoid transport to smelters) and allowing mine-life extension developing a new business-model concept based on high efficient recovery of complex ores that will ensure mining industry competitiveness and employment.

In case of any further question, please contact us at office@intmet.eu.